Introducing UltraShield™

The film coated solution for safely storing innovative drugs

YOUR CHOICE — OUR SOLUTION

As a strategic partner and leader in the pharma packaging industry, Datwyler has developed its own film coating technology, becoming the first and sole supplier capable of offering both film and spray fluoropolymer coating technologies for elastomeric closures.

This extended range of coating options is designed to meet the highest demands for quality and performance for large and sensitive molecule drugs, allowing Datwyler to respond even better to specific applications and customer preferences.

"We want to become the most valued partner for parenteral packaging to the

pharmaceutical industry by offering best-in-class products with a strong presence in

new drug developments while leveraging our state-of-the-art global footprint."

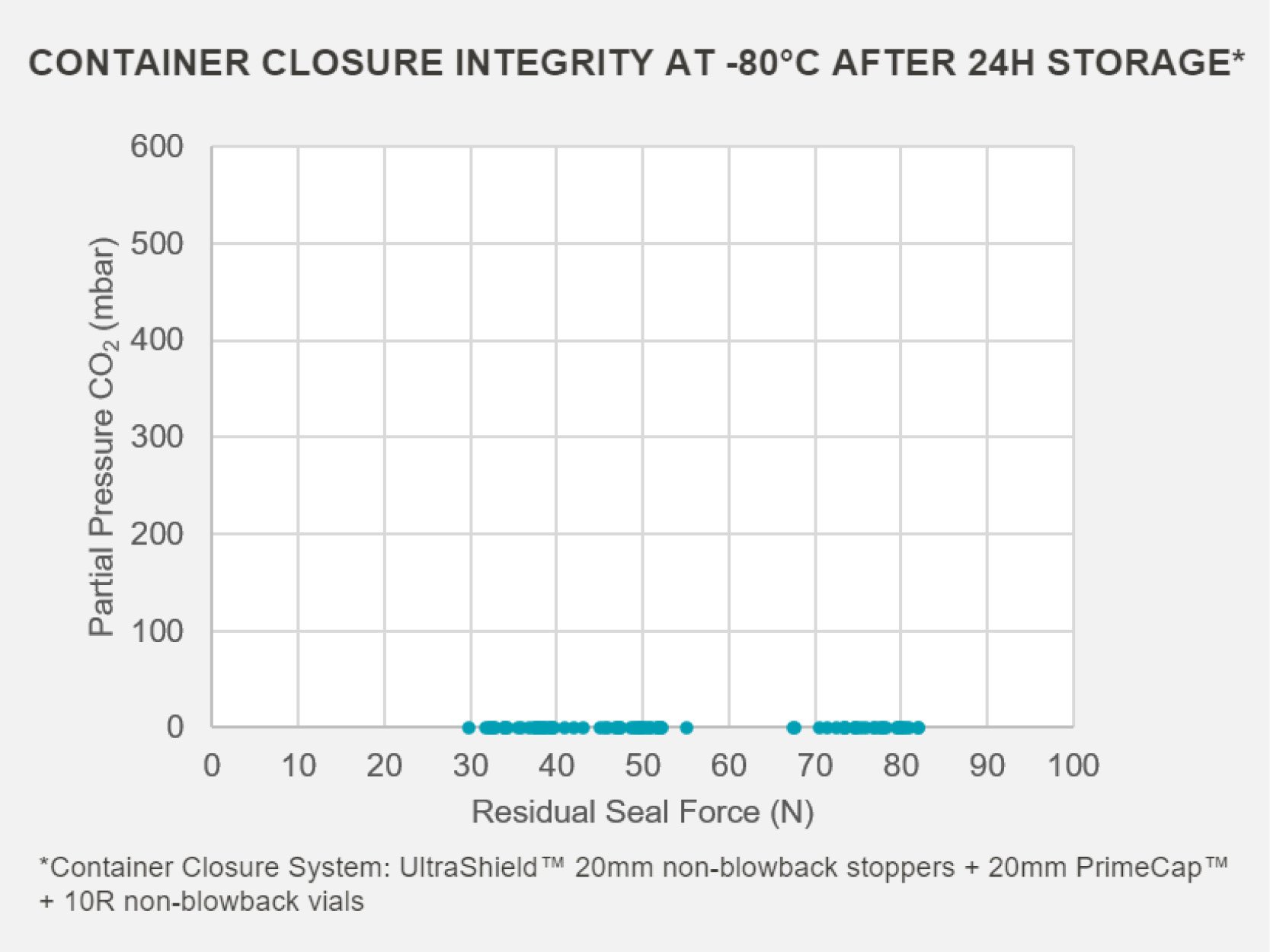

Robust to Ultra-low Temperature Storage

An efficient seal enabling the secure storage of drugs under ultra-low temperatures up to -80°C with a broad range of crimping parameters.

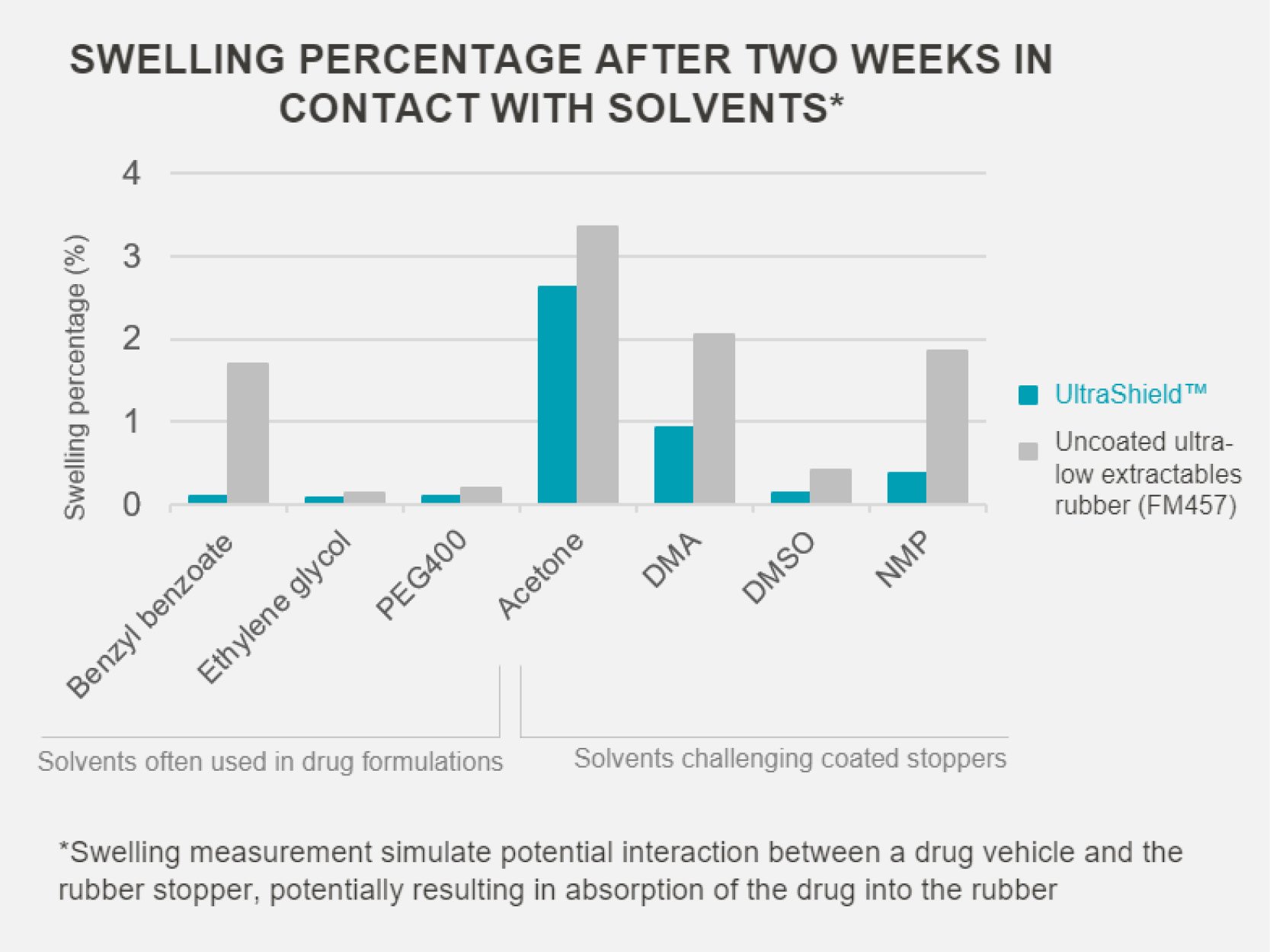

Strong Barrier to Aggressive Solvents

The film barrier limits drug-stopper interaction and forms an ultra-protection against aggressive excipients.

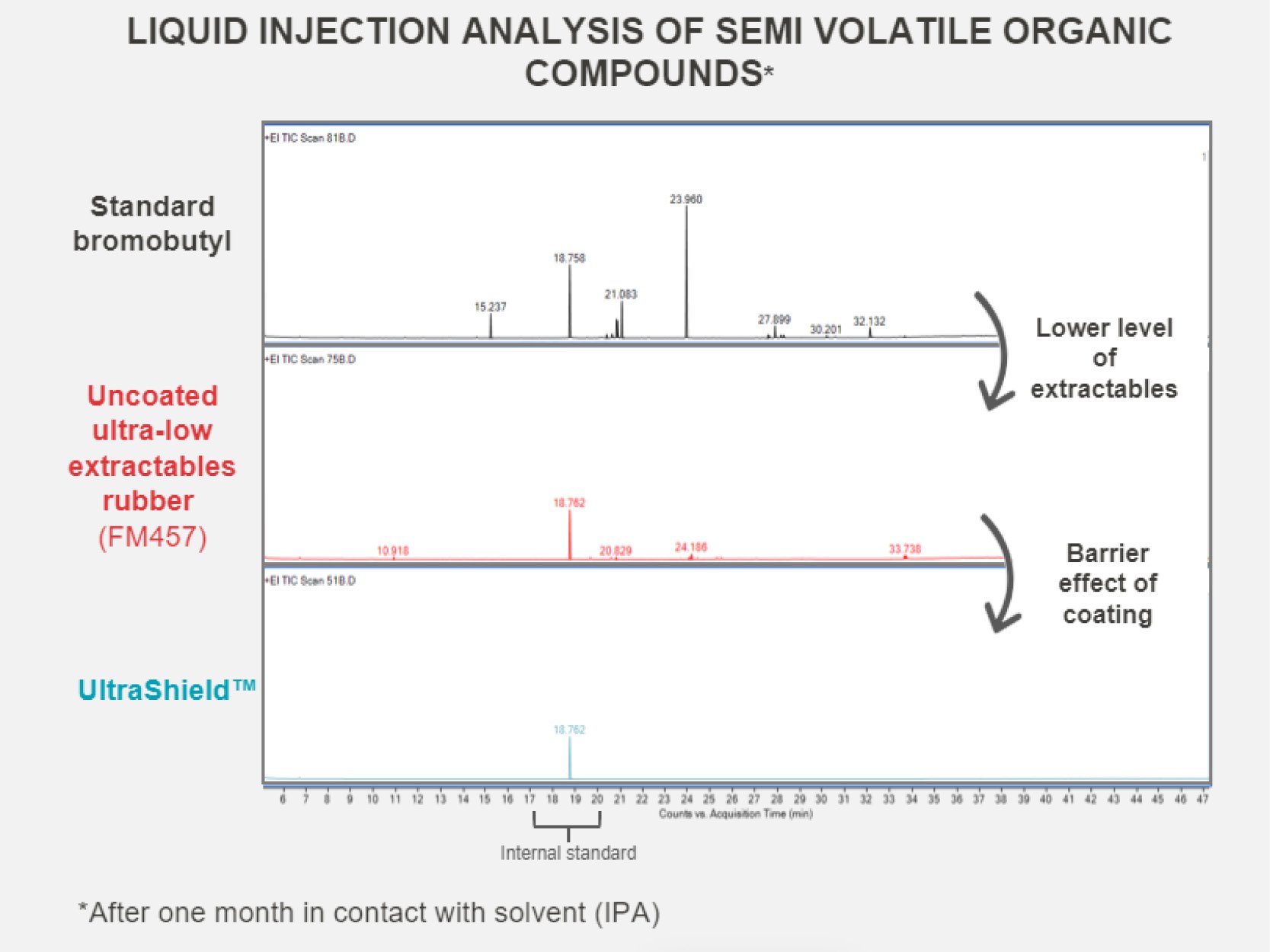

Superior Chemical Compatibility

Ultra-low extractables bromobutyl rubber substrate FM457 on which is applied a fluoropolymer film that covers the complete drug contact area and forms a barrier to obtain a best-in-class extractables and leachables profile.

Highest Quality Standards

UltraShield™ is manufactured according to Datwyler’s FirstLine® concept ensuring the highest quality levels on the market.

“With best-in-class extractable and leachable profiles and the highest quality standards, both UltraShield™ and OmniFlex® have a unique set of value-added features that makes them complementary in addressing any of our customers’ needs with the ultimate solution.”

UltraShield™ Product Offering

.jpg?width=1000&height=648&name=UltraShieldTM%20Stoppers%20-%20picture%20for%20web-site%20(1).jpg)